| Name |

Image |

Authorized Retailer |

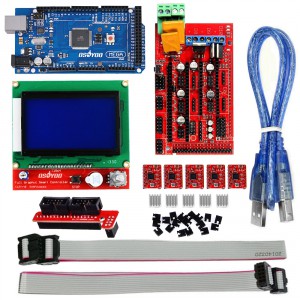

| 12864LCD 3D printer kit |

|

|

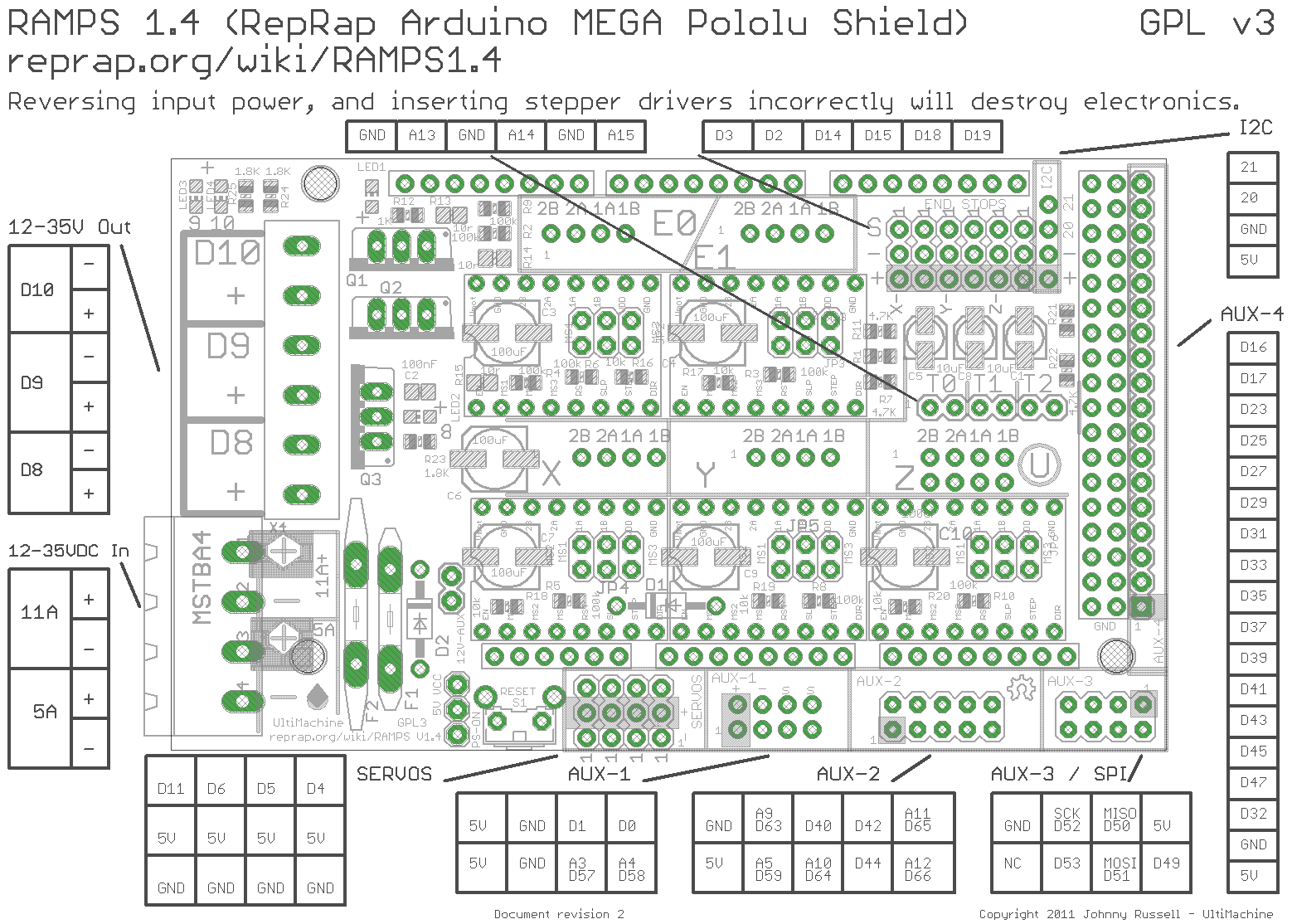

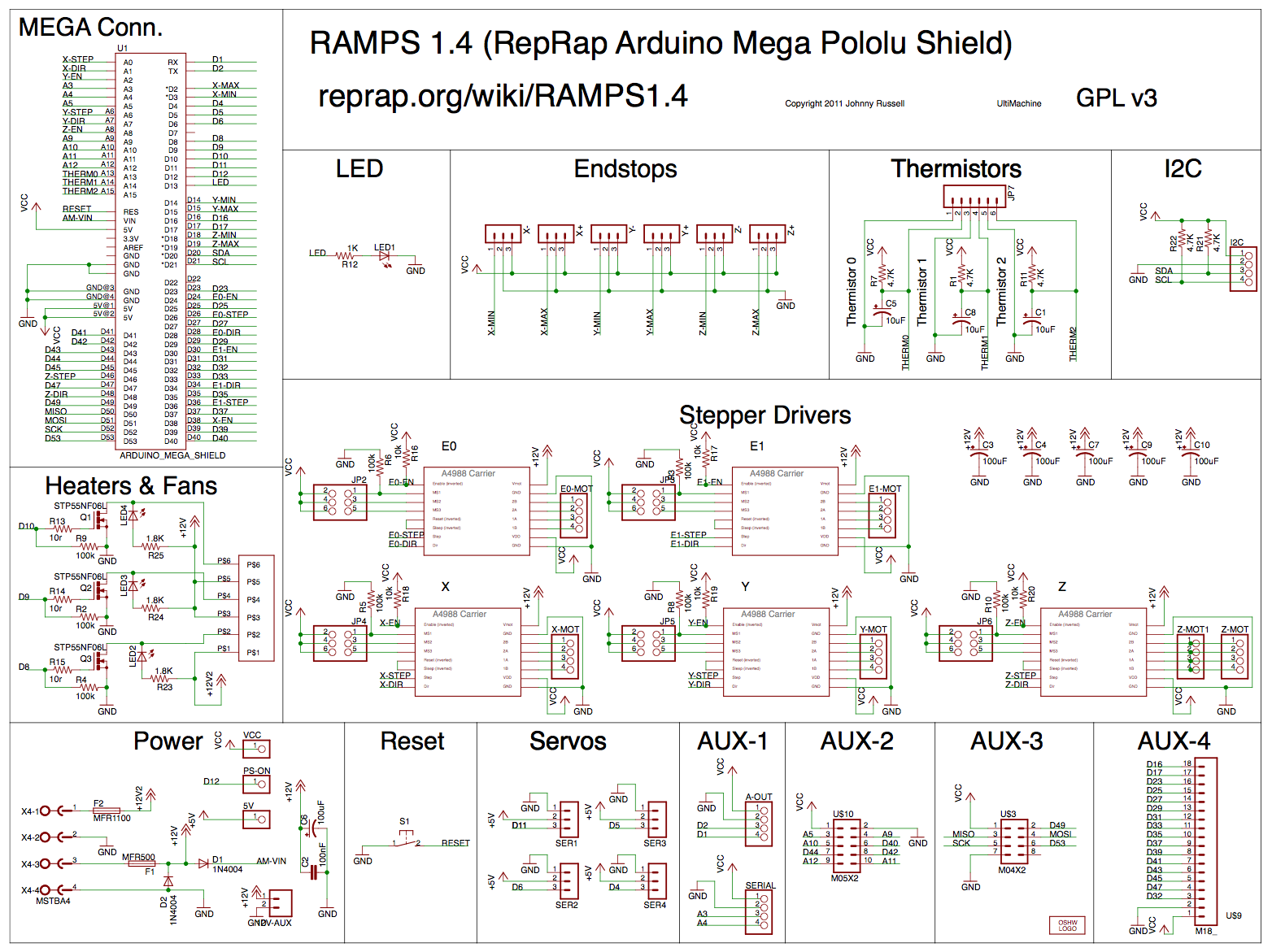

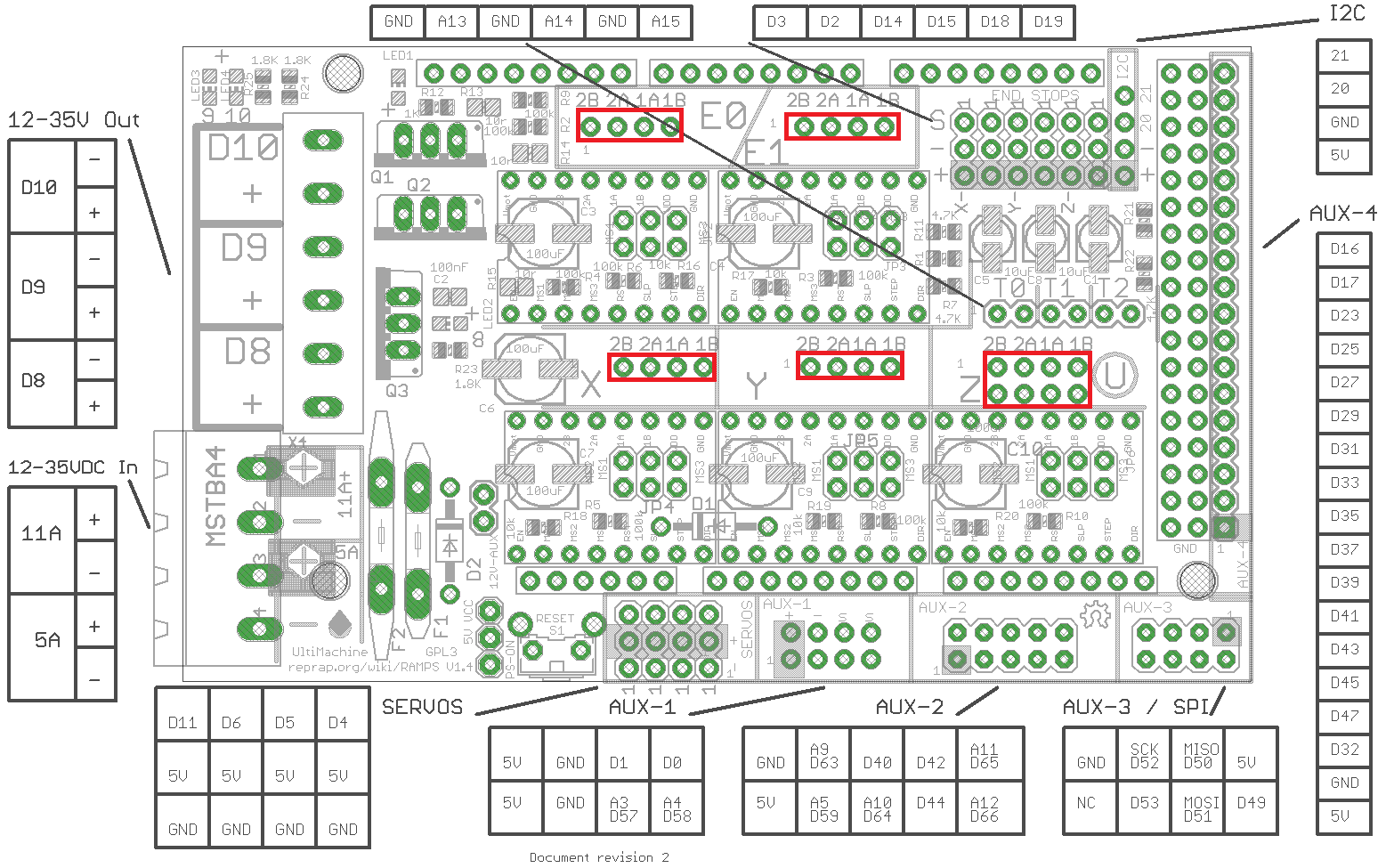

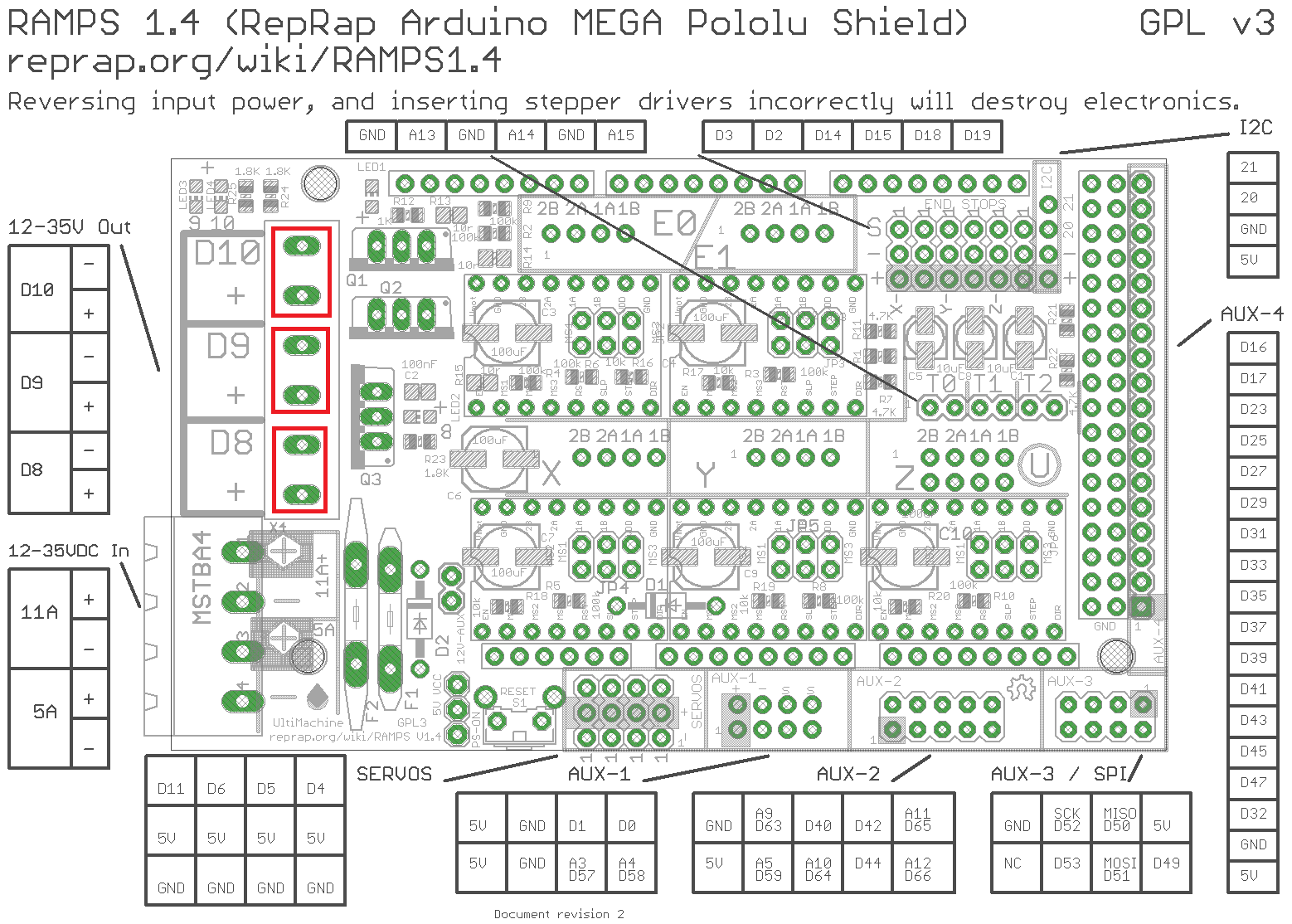

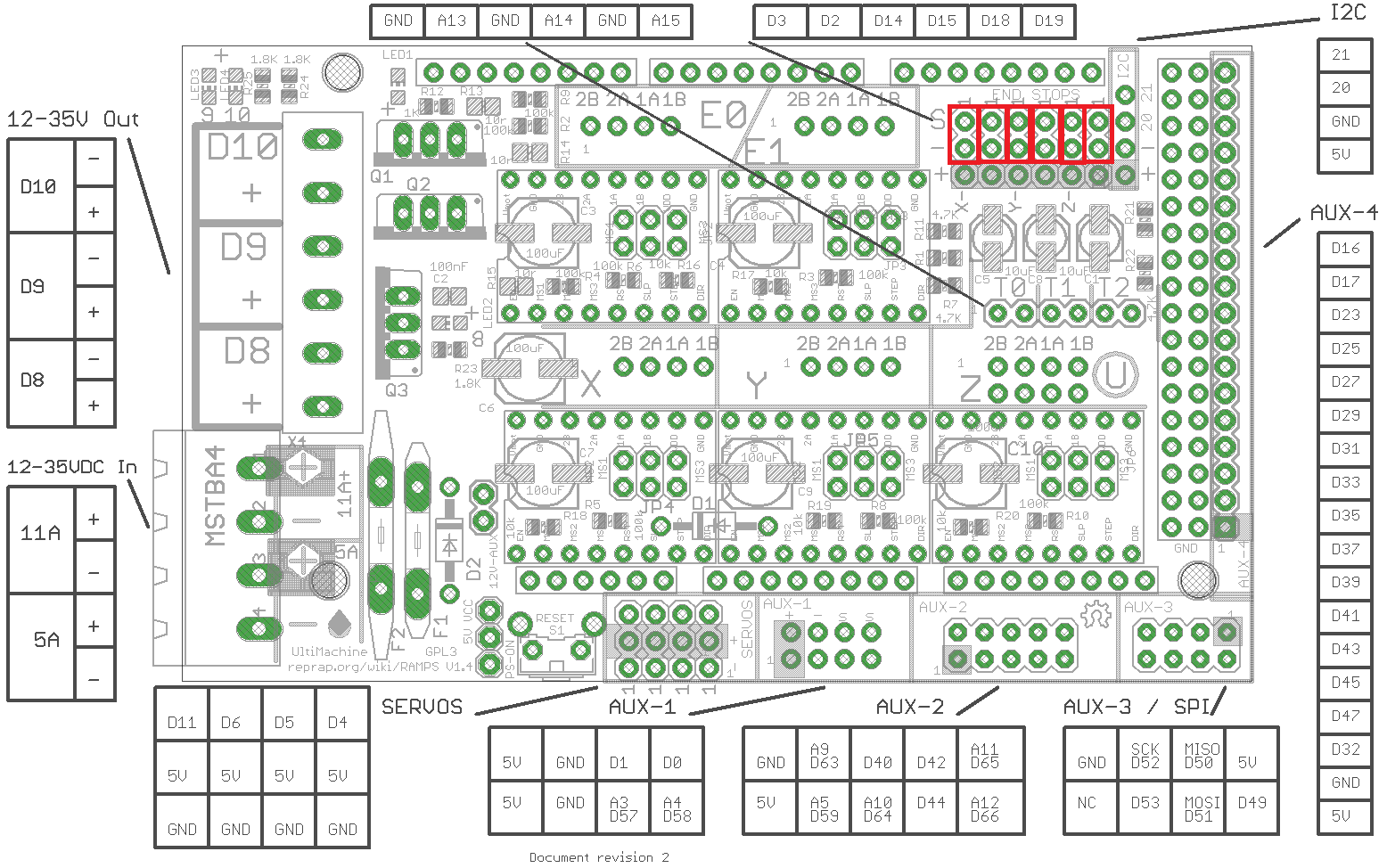

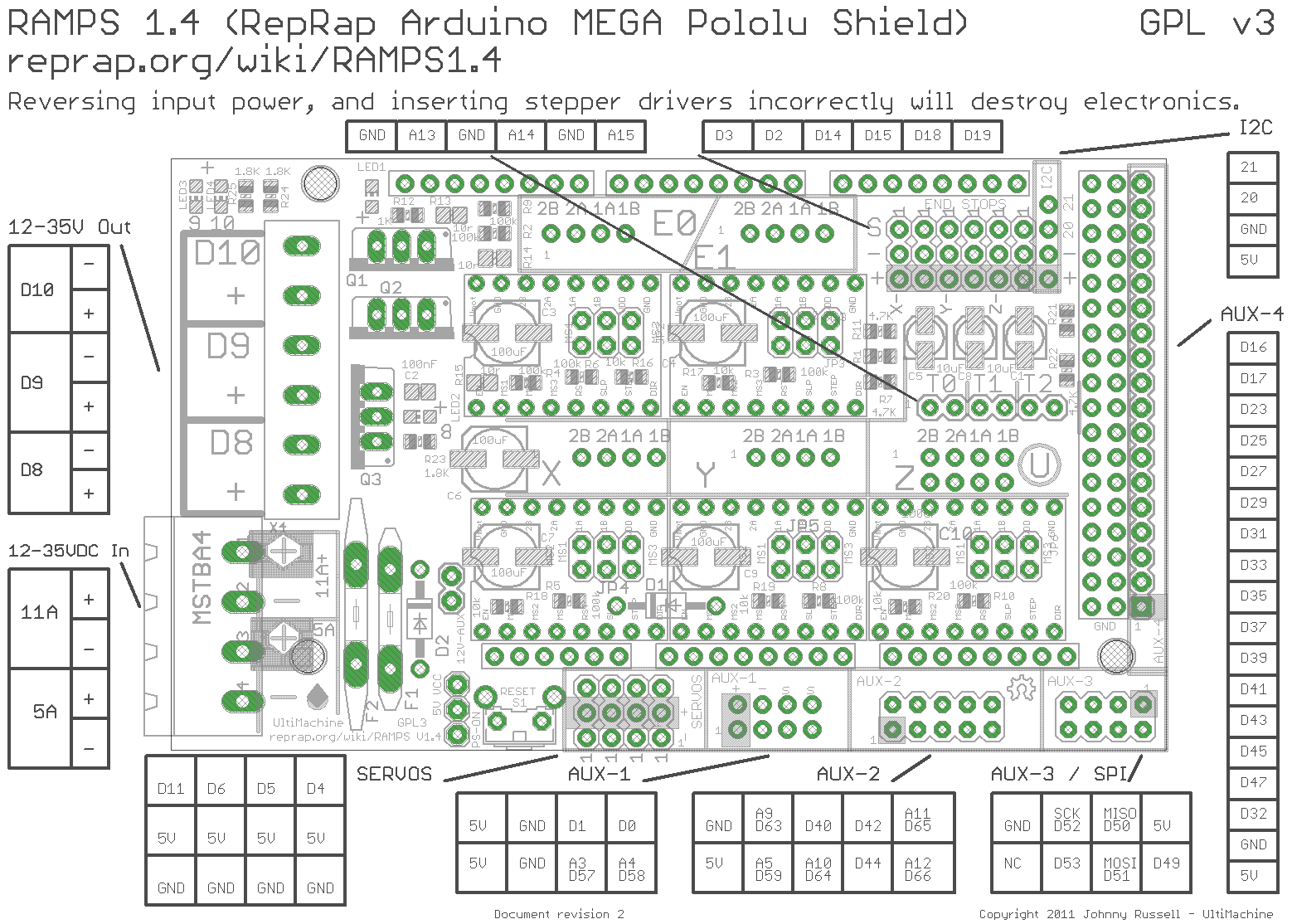

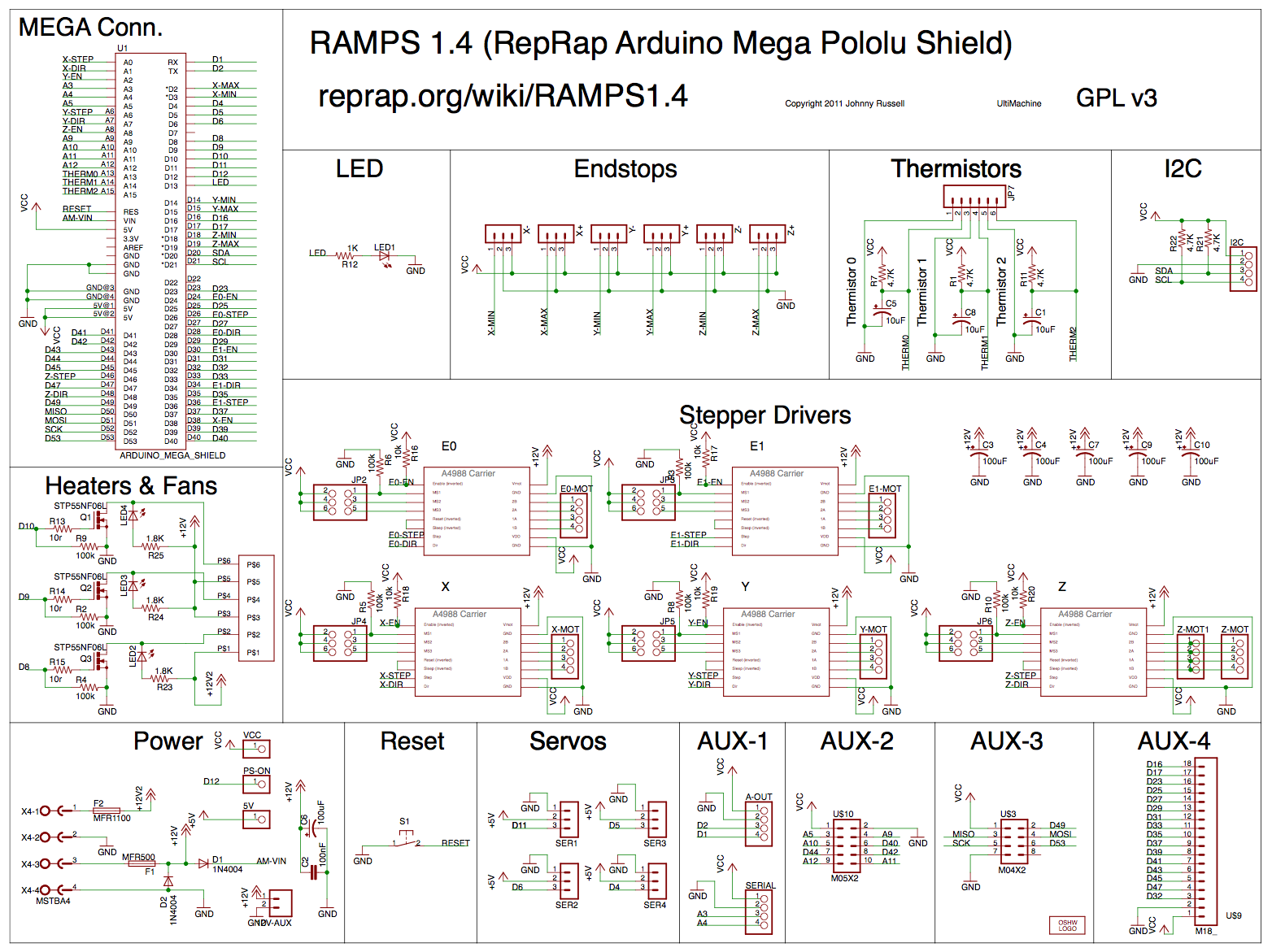

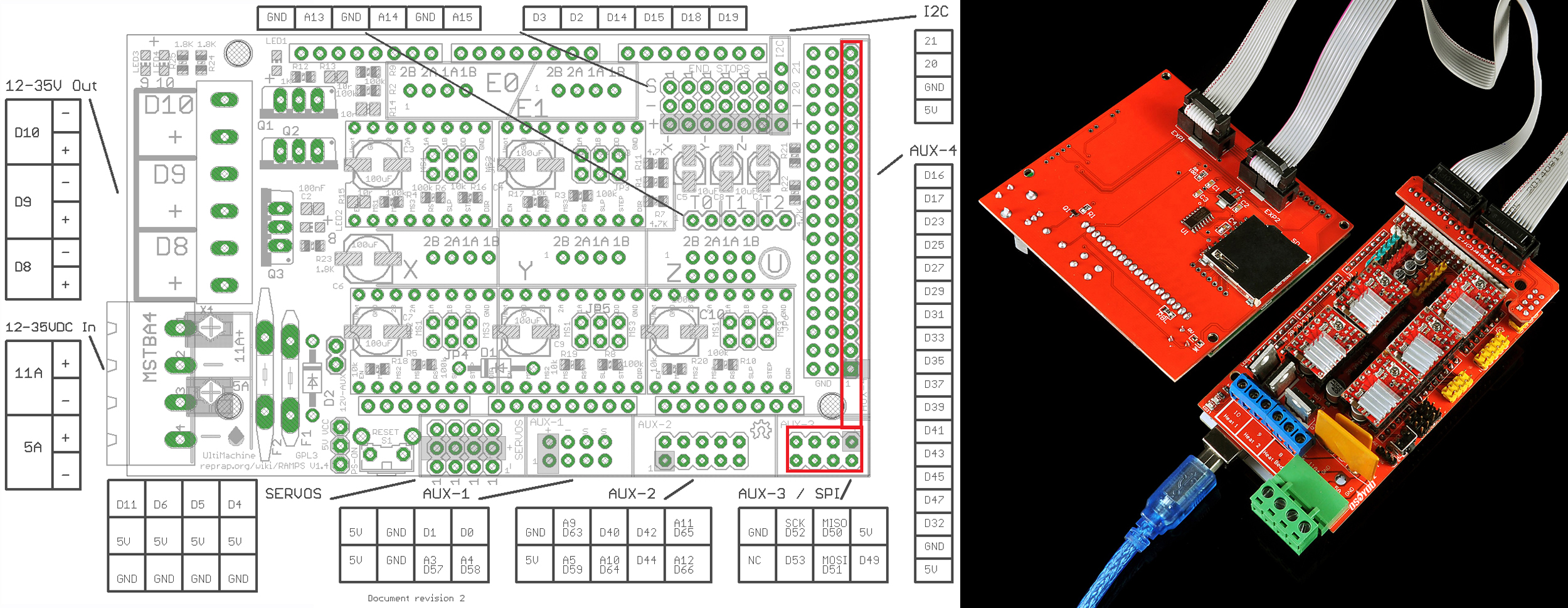

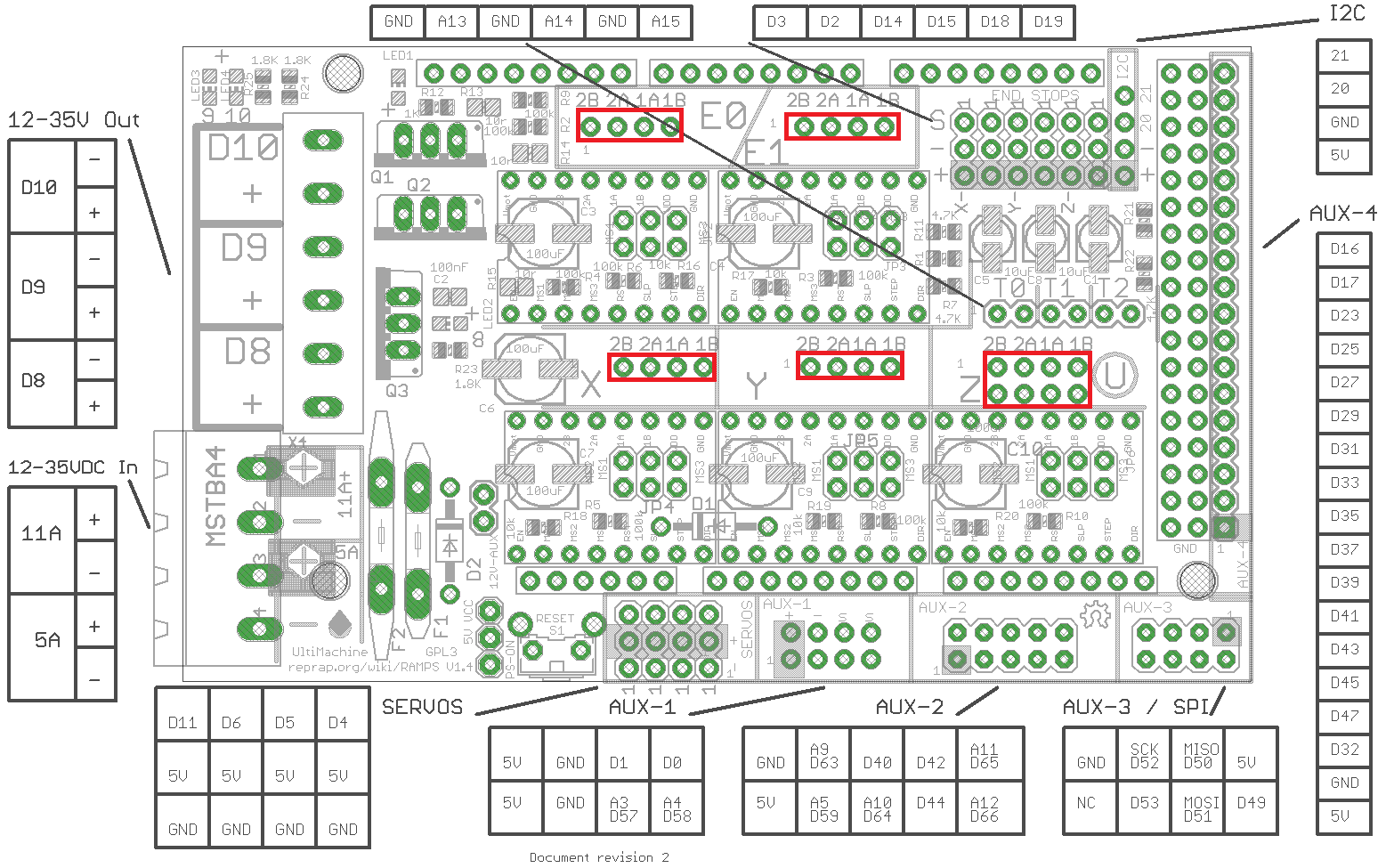

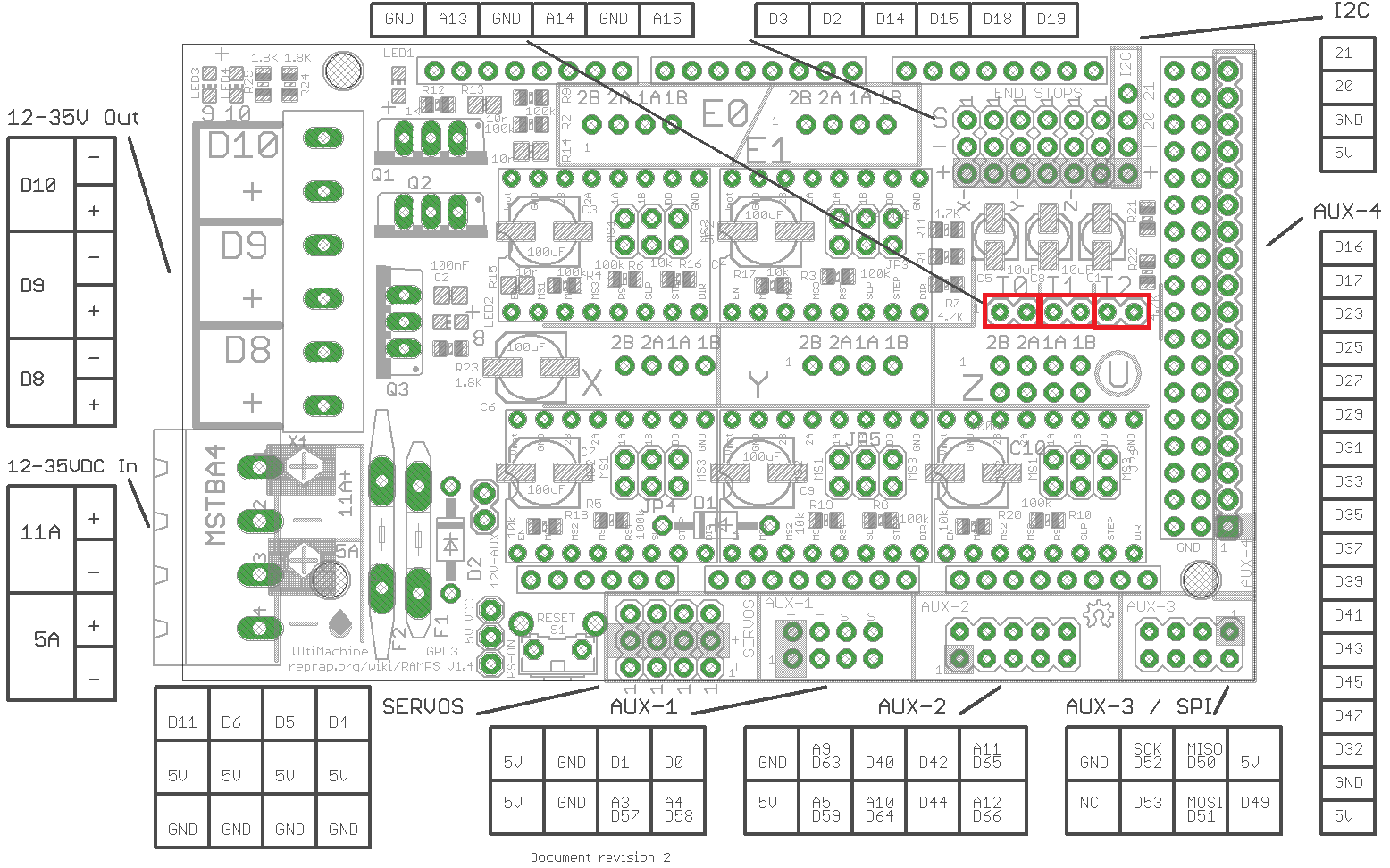

1 RAMPS 1.4 Schematic:

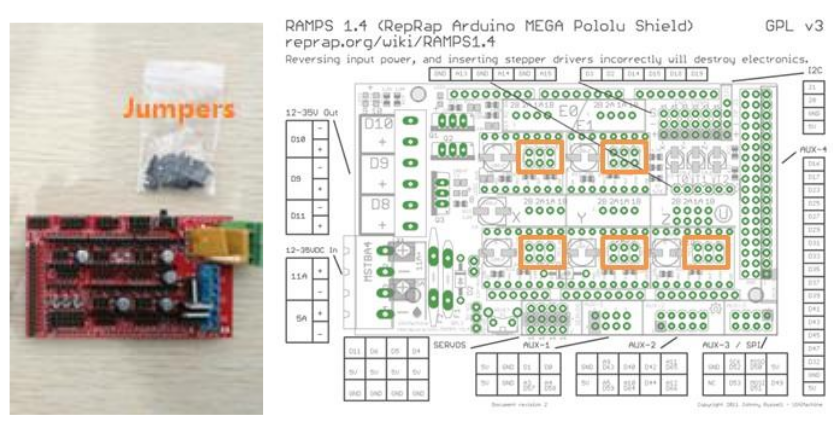

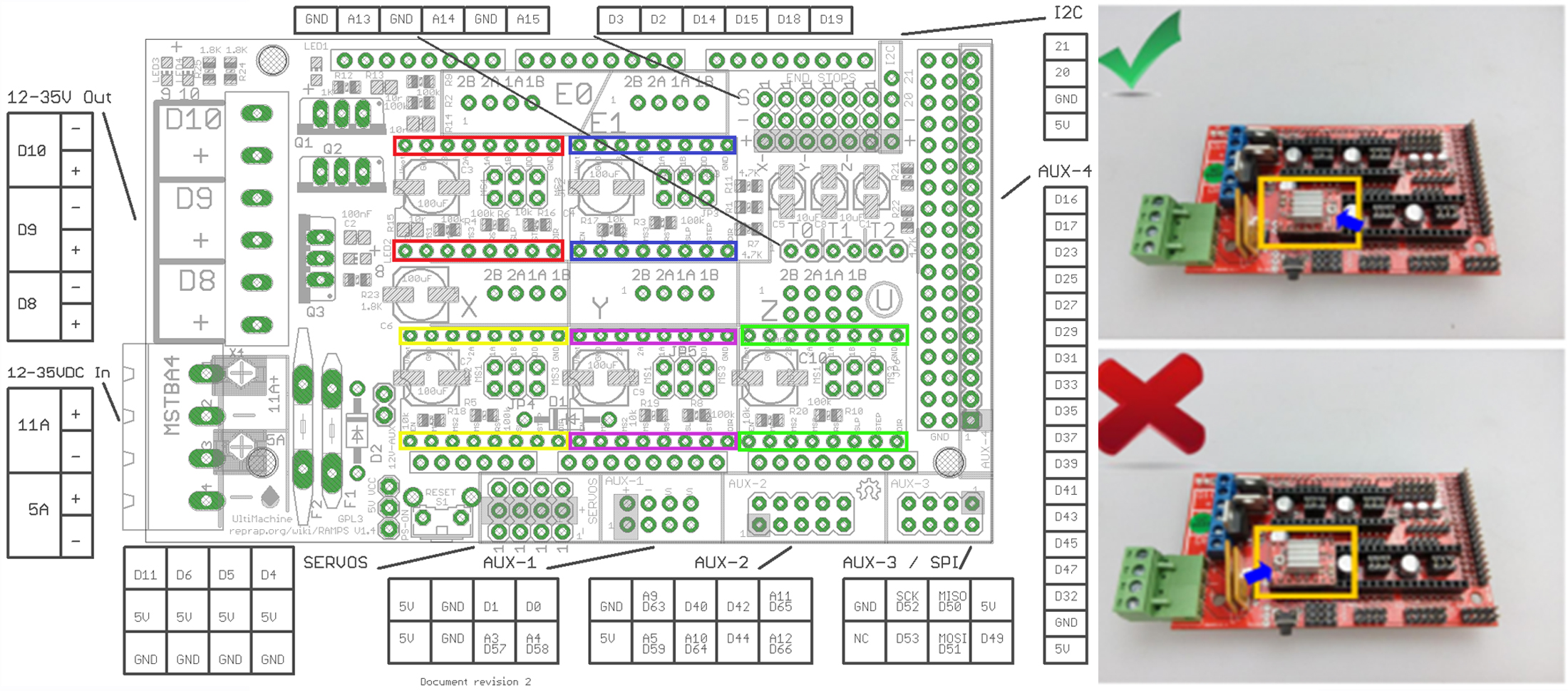

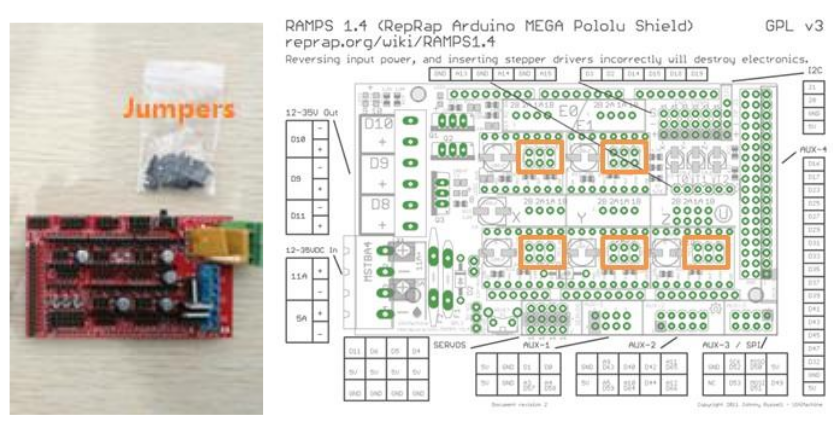

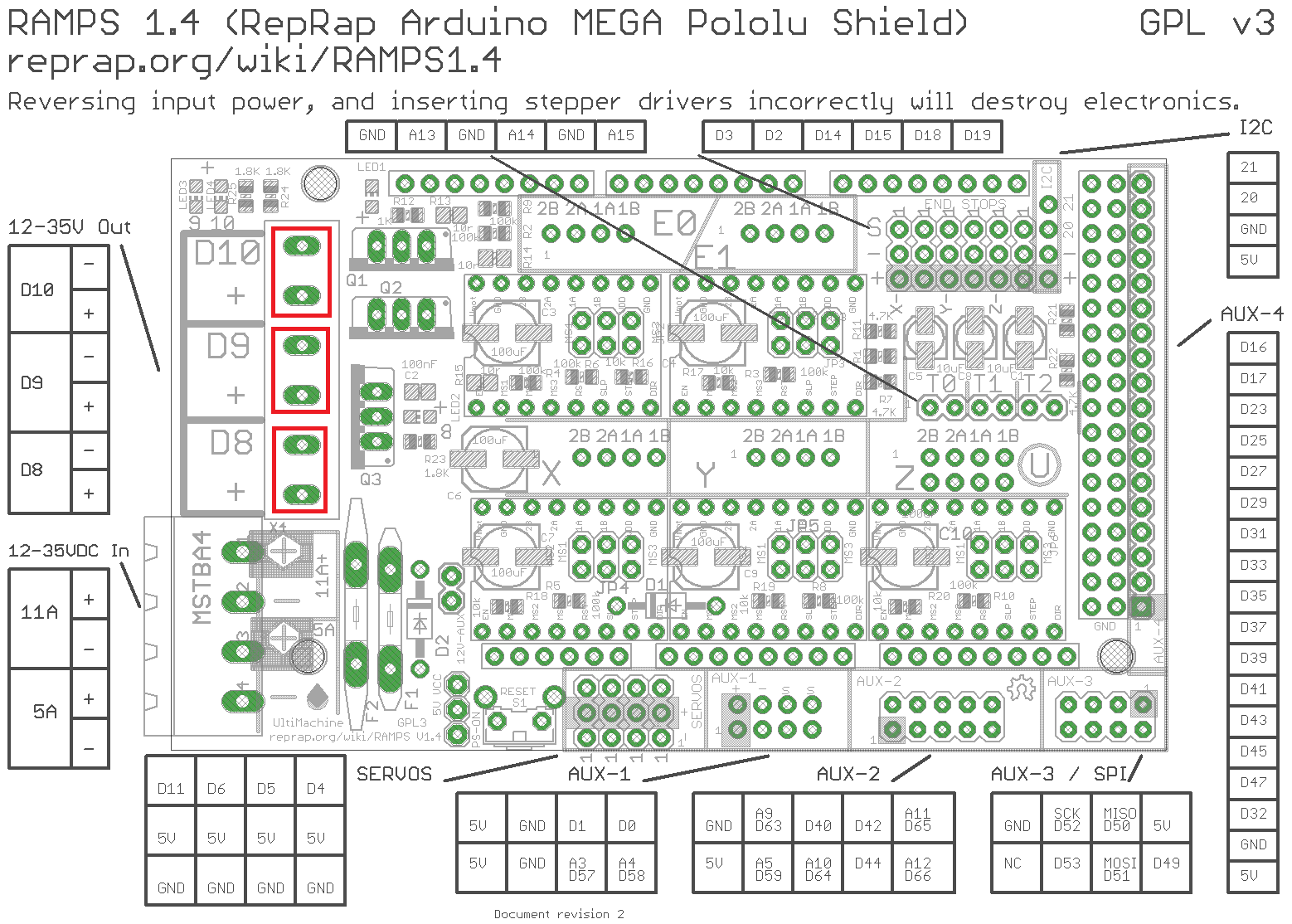

2.Insert jumpers to RAMPS 1.4

The jumpers (in the plastic bag below) control the precision of the motor movement. To have the most precise stepping (1/16micro stepping), insert three jumpers to each of the areas outlined below:

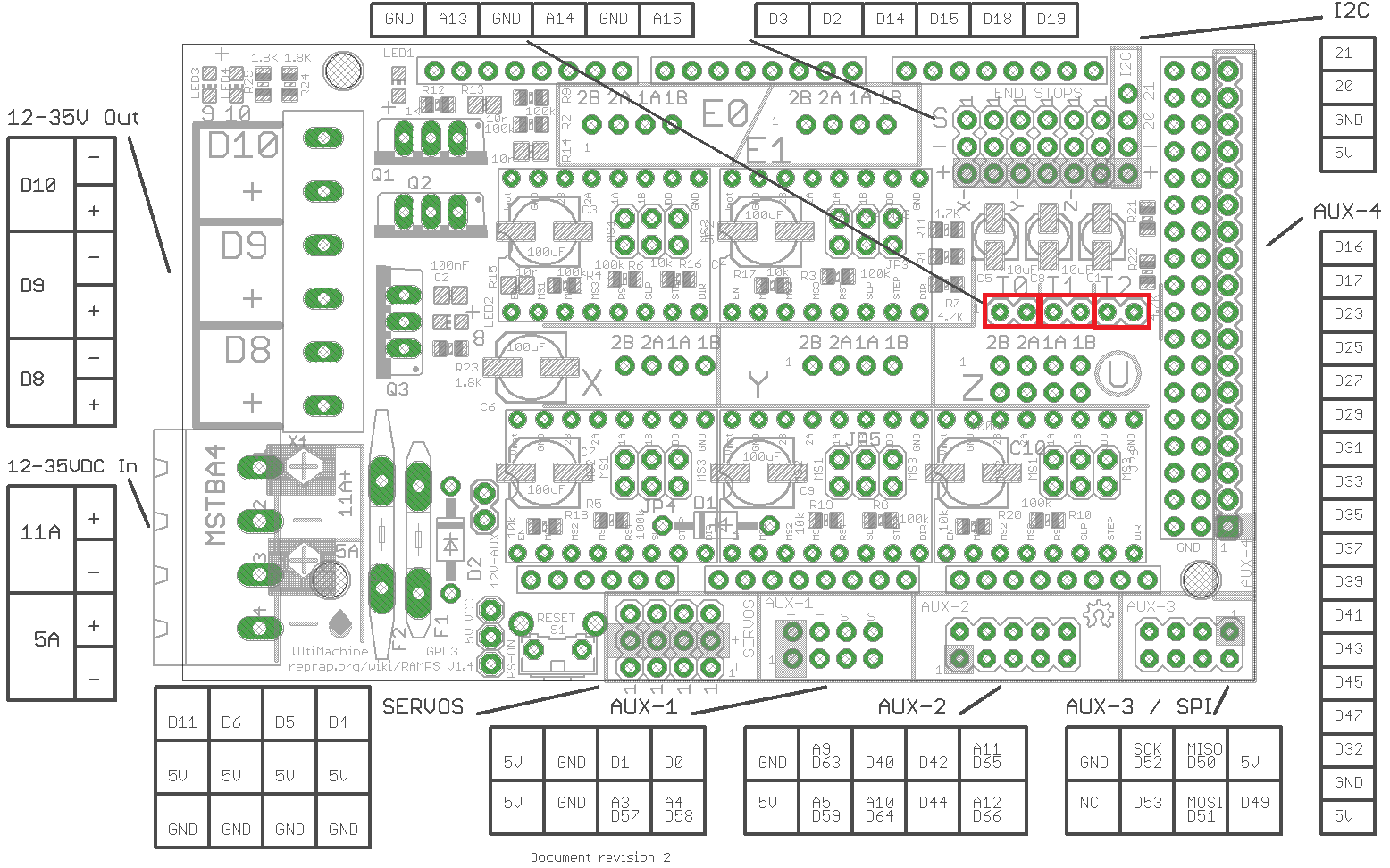

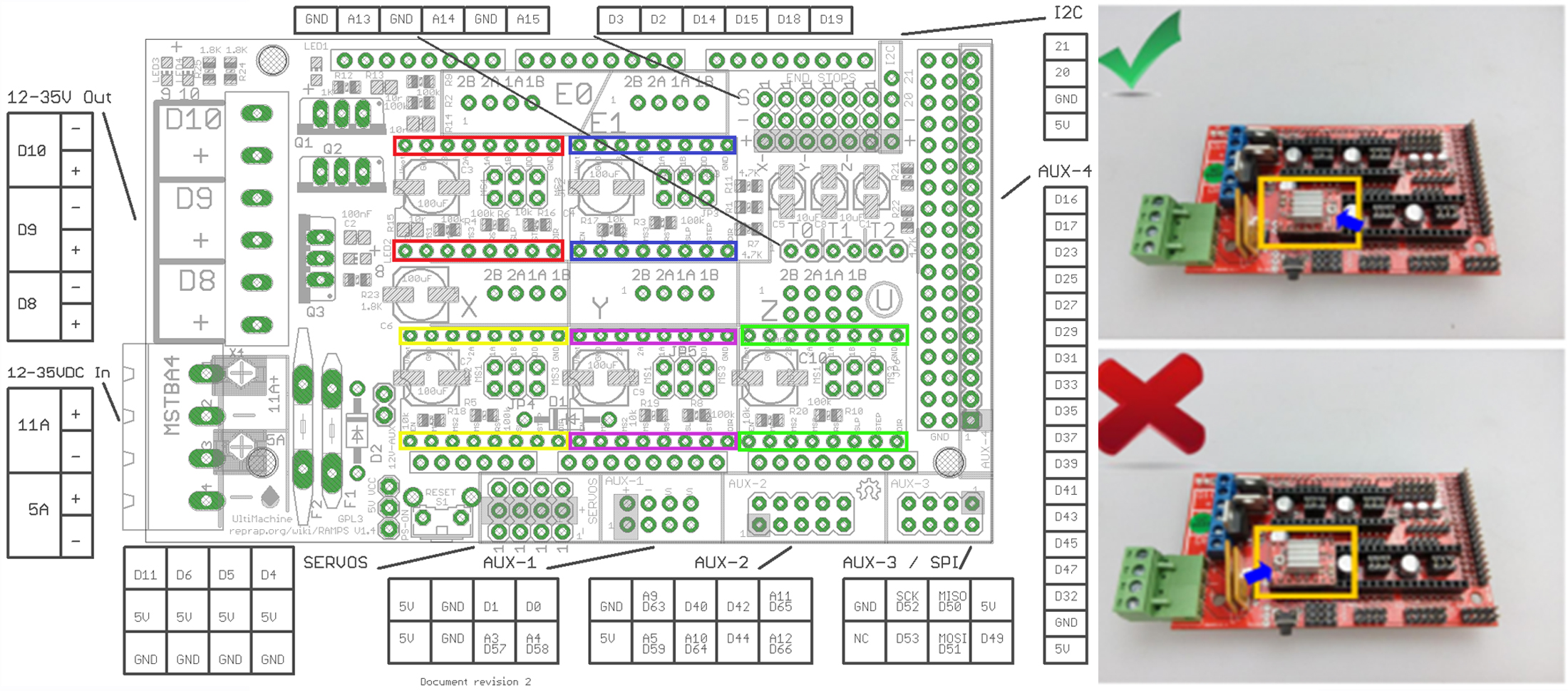

3.Install A4988 driver on Ramps 1.4

MAKE SURE THE ORIENTATION IS CORRECT AS SHOWN BELOW! The potentiometer should be facing away from the “D10 D9 D8” side on the RAMPS 1.4 shield. We have heard numerous cases where these steppers got fried because of incorrect orientation. Install the heat sinks on the stepper drivers, and make sure the heat sink are not touching multiple components on the stepper driver(the clearance could be small, but it is there!)

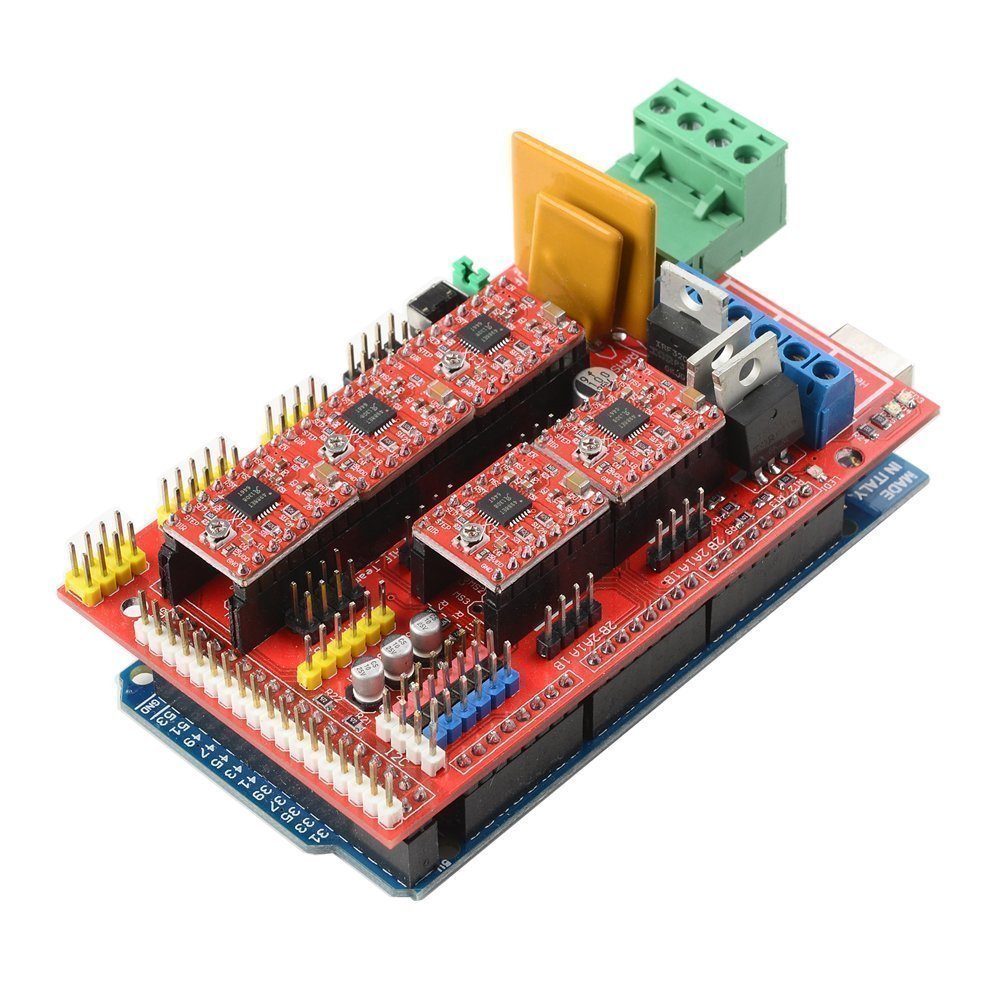

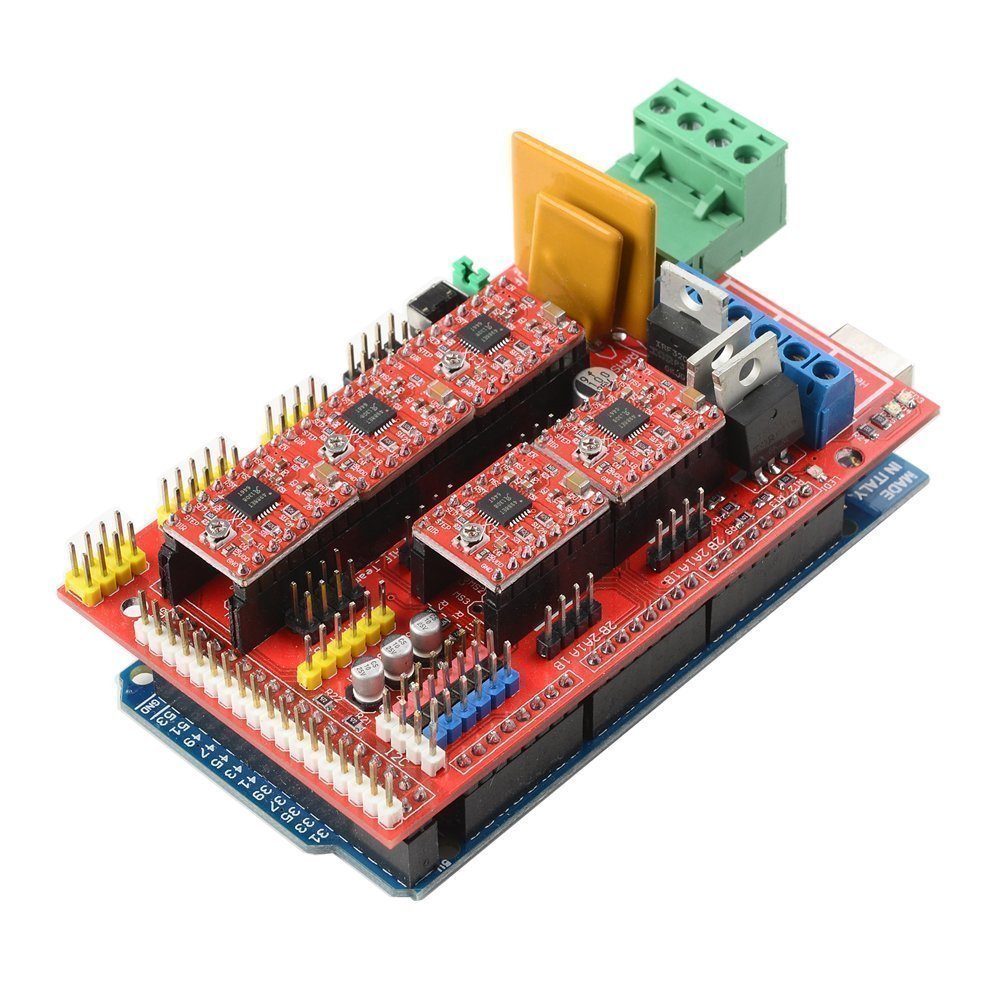

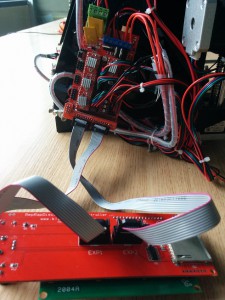

4.Install the RAMPS 1.4 on top of Mega 2560 Boards

The Mega 2560 board’s USB side is directly under RAMPS 1.4 shied’s “D8 D9 D10”area.

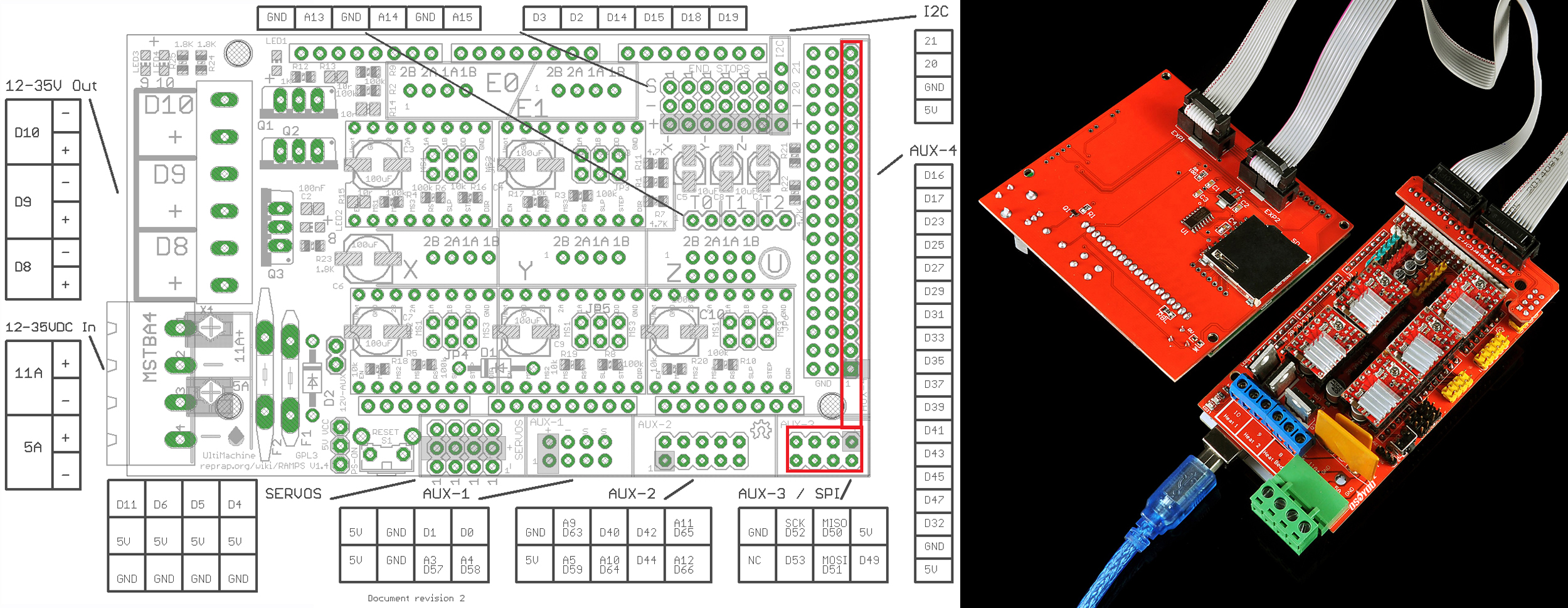

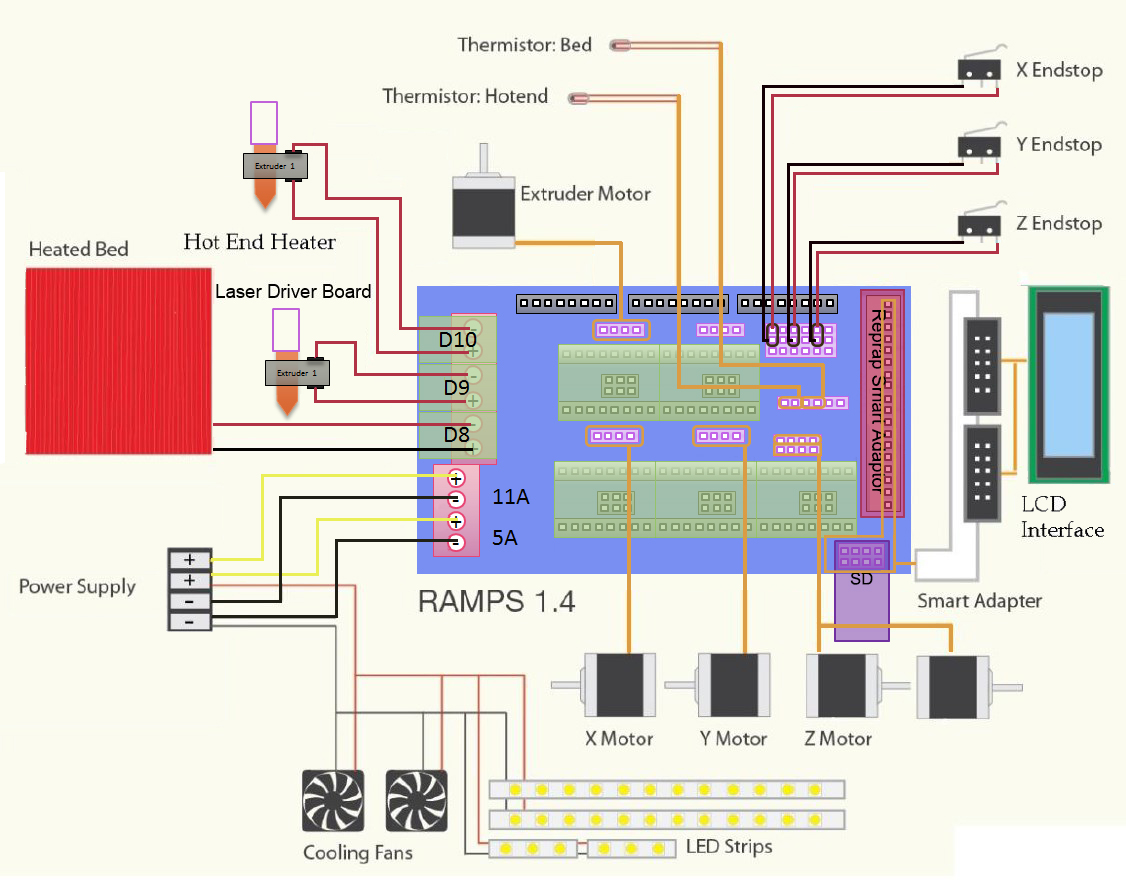

5.Install the 12864LCD/2004LCD on Ramps 1.4

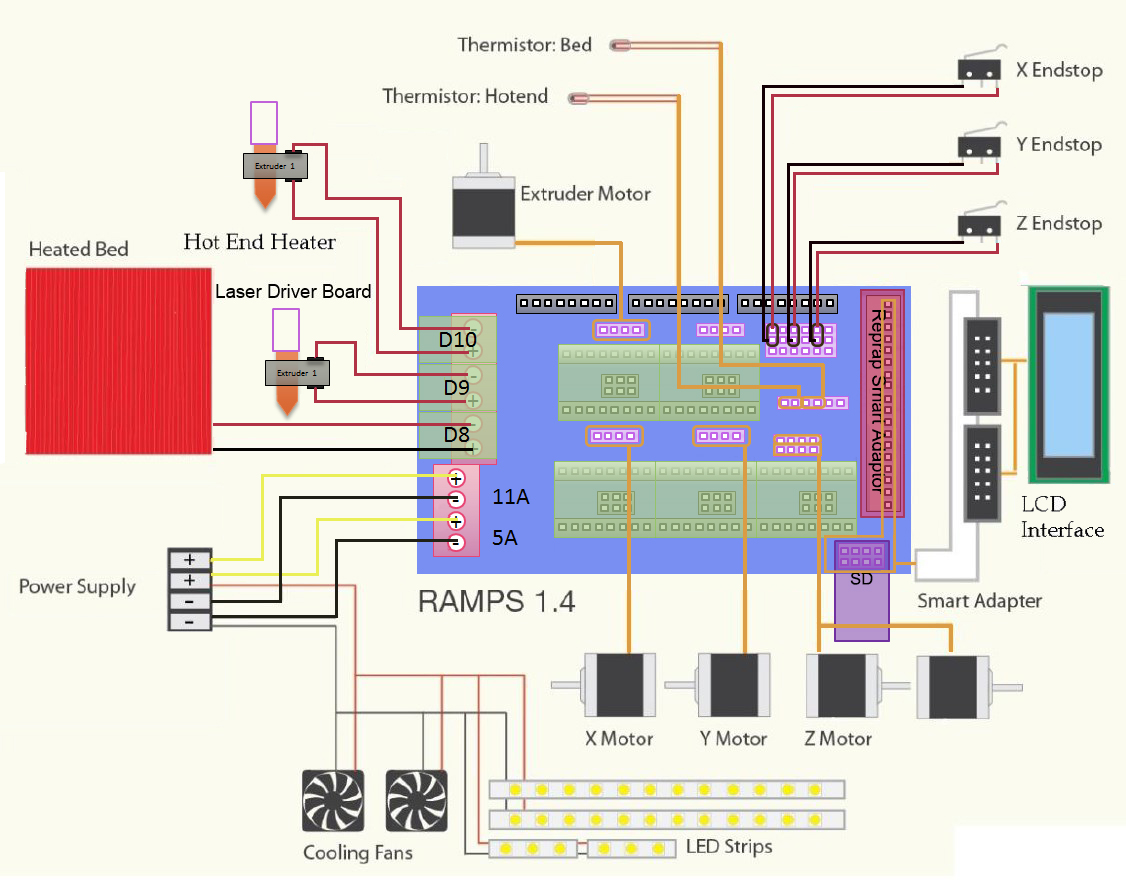

6.Connect power, Motors, Thermistors, Hotend, Heatbed, and Fan.

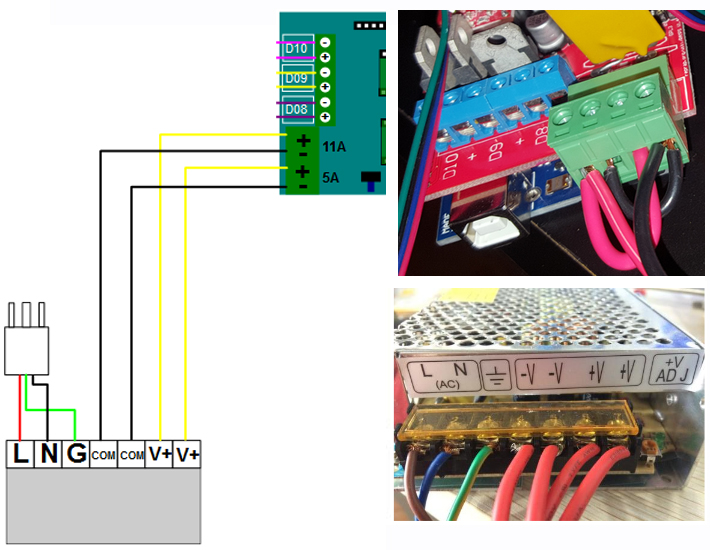

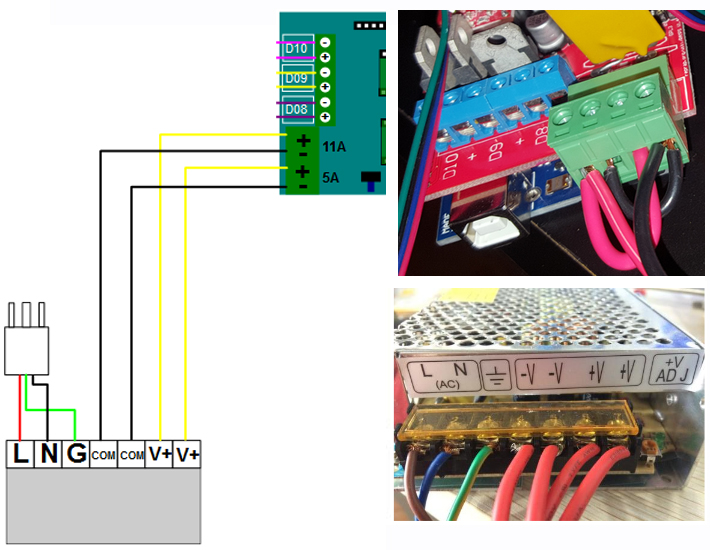

6.1 Connect Power

Connect your 12V power supply to the RAMPS shield. Reversing +/- or otherwise incorrectly connecting power can destroy your electronics and cause fire hazard. Get four spare wires and connect them on the two Com(V-) and the two V+ nodes. Connect the other ends to the RAMPS 1.4 shield’s power input nodes: (The first one on the bottom is COM(-V), then V+, then Com, then V+ again as shown below)

6.2. Connect Stepper Motor

The RAMPS board contains connectors for the X, Y, Z, E0, and E1 stepper motors. The Z connector is actually doubled so that you can plug 2 separate stepper motors into this one stepper driver. E0 and E1 are for your extruder stepper motors – if you have a single extruder on your machine, then you’ll use E0.

ATTENTION: Don’t use homing of the axis at this point!

With homing the firmware moves all axis until it hits the endstop. If the stepper turns into the wrong direction the head or the bed will run into the wrong direction until it hits the mechanical end of the axis. You can only stop this by resetting the printer or turn of the power

6.3 Connect thermistors

From left to right: Extruder 1 thermistor, heat bed thermistor, and extruder 2 thermistor. These are not polarity-sensitive. The thermistor leads need to be electrically isolated from each other – tiny Teflon tubing is best for this.

6.4 Connect Hotbed and extruder

Plug in extruder 1 heater to D10, heatbed heater to D8, and fan(or a second extruder) to D9. Only the fan is polarity-sensitive

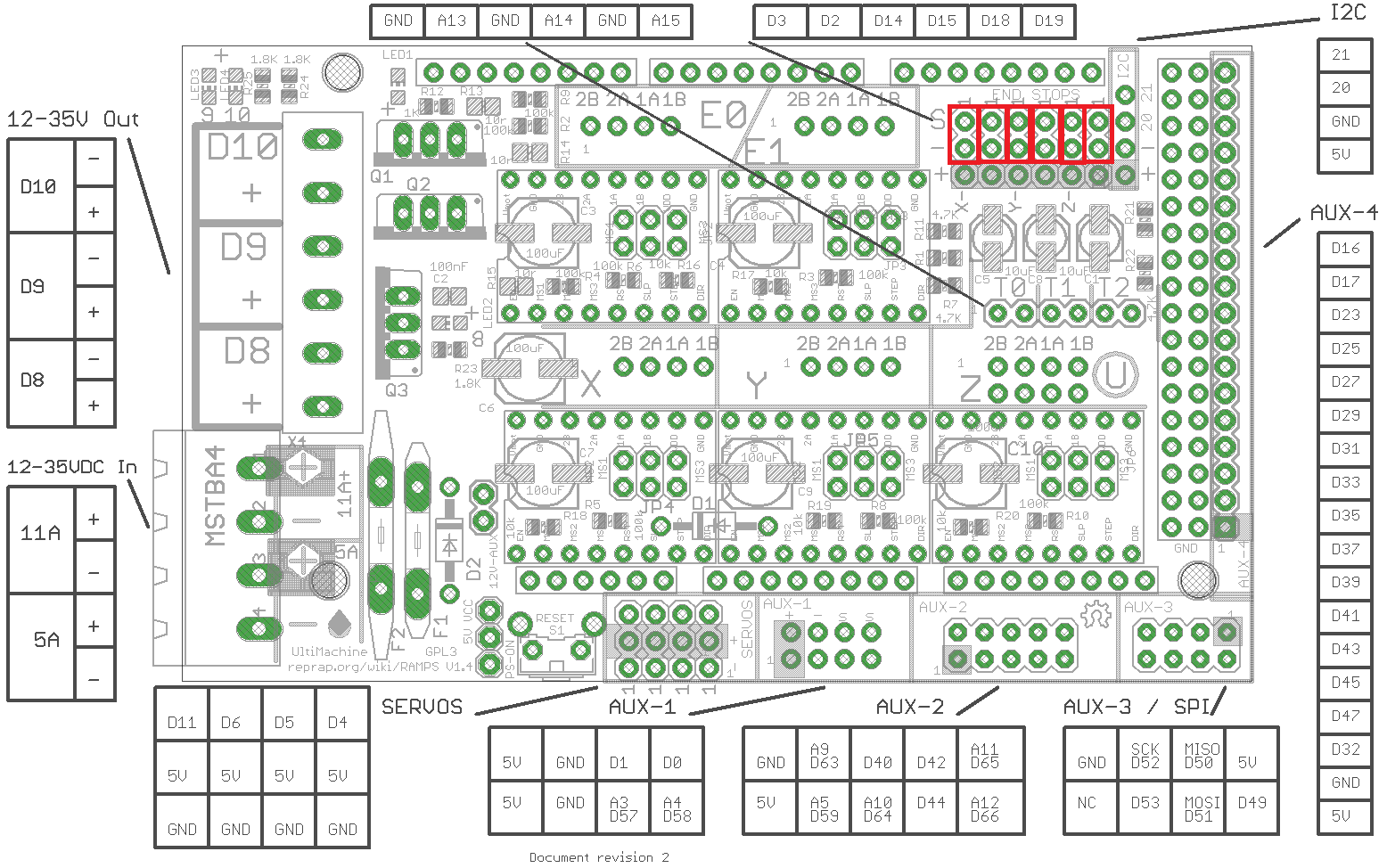

6.5 Endstop Connections

From left to right of Ramps 1.4, each column corresponds to xmin, xmax, ymin,ymax, zmin, and zmax.

The mechanical endstoppers are polarity sensitive. Solder wires to the “COM” and “NC” leads. Connect these two leads to the top two rows in the endstopper area outline below, with COM on the bottom and NC on top. If you are using optical end stopper, then you will need all three pins.

In common usage, everyone just wires up an endstop to the minimum (zero point) for each axis, and then uses the software limits in the firmware to keep the printer from going too far in the opposite direction.

7. Scene graph

.

.

were is pin D7 located im building a custom project and need it